The ancient alcohol yeasts of our forefathers, leaf yeast and Chinese yeast, are still commonly utilized today and contribute to the distinct flavor of traditional alcohol, which is difficult to find outside of Vietnam. However, these two strains of yeast still have drawbacks, including low economic efficiency, a protracted fermentation period, and a flavor that is "difficult to drink" for the majority of people worldwide. Most well-known industrial beer and wine brands use industrial wine yeast as a result of the use of contemporary technology. Let's find out more about this yeast line with Viet Wine.

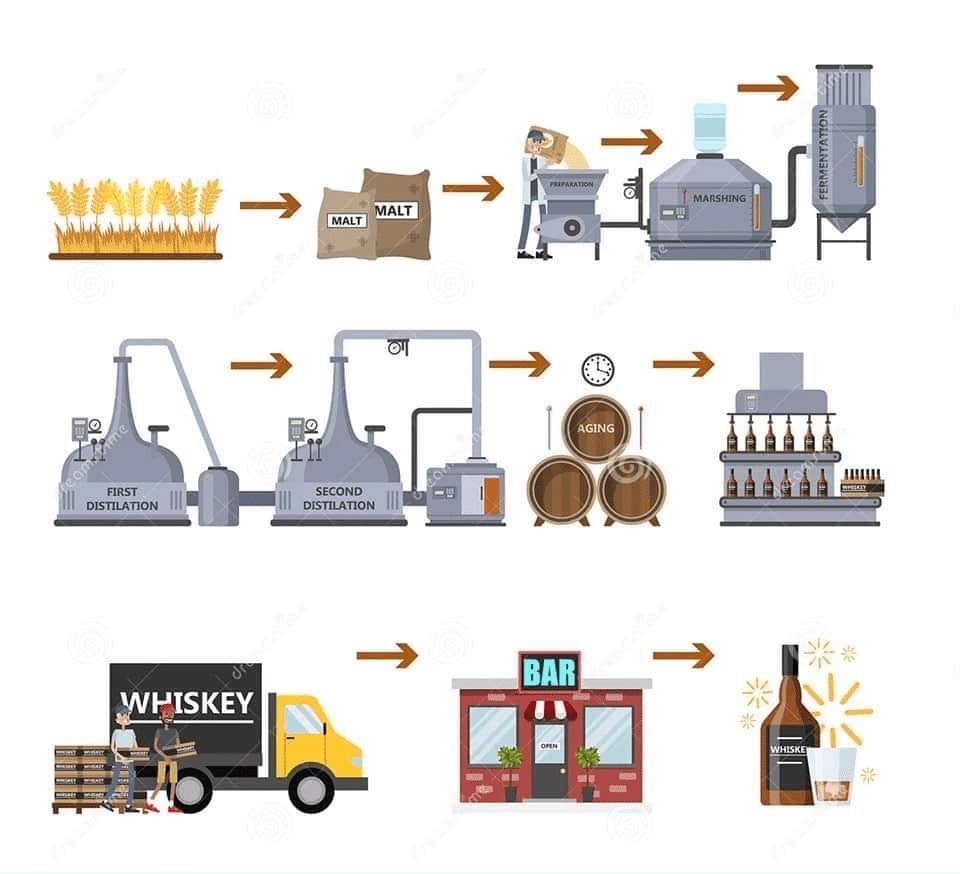

To understand industrial yeast, first learn about the industrial alcohol making process.

Industrial alcohol making procedure

In contrast to traditional alcohol making, industrial alcohol making typically uses a standardized procedure along with cutting-edge machinery and contemporary technology to produce vast amounts of high-quality alcohol.

The ultimate result of this technique is employed in the medical and bartending industries in addition to being consumed as wine.

In order to keep things concise, Viet Wine breaks down the four main processes of the industrial alcohol making process as follows:

- Saccharification

- Utilizing industrial yeast for fermentation

- Utilizing industrial yeast for fermentation

- Distillation and purification

Based on learning, watching, and testing, the analysis processes below represent the author's personal understanding. It may be viewed as a method; every manufacturer has their unique approach, but the principle is the same.

1. Handling of raw materials

Starchy foods, such as cassava, corn, potatoes, and rice, are the raw materials that are fed into grinding machines from enormous containers. After grinding, the increased cross-sectional area will cause the material size to decrease and the oxidation reaction to speed up.

By doing this, the structure of the plant cell membrane is broken down, which speeds up the saccharification process and makes it easier for the inner starch granules to escape the outer shell.

After that, a specific ratio of water and rice flour is combined at 30 to 40 degrees Celsius. Accompanied by a quantity of the amylase enzyme (which is present in large amounts in human saliva), usually it is about 20-30% of the amount of enzyme prepared for a batch. After boiling for 40–50 minutes to attain 85–87 degrees Celsius, the entire solution will be kept for 15–20 minutes. To dissolve big starch particles, keep boiling for 50–60 minutes. Finally, this liquid will then be transferred to the saccharification tank.

2. Saccharification

The newly cooked starch solution will be cooled to around 90 degrees Celsius in the tank, and then 70-80% of the leftover enzyme will be added. Continue to cool this solution to 55-56 degrees Celsius, then leave it for 30 minutes before cooling again to 28-30 degrees Celsius.

3. Utilizing industrial yeast for fermentation

Industrial yeast will be added to the powder solution obtained in step 2, then covered securely and kept at a constant temperature to convert sugar into alcohol and a by-product mixture of water and residue known as Chin vinegar (wine vinegar). men công nghiệp vào, đậy nắp kín và được cấp nhiệt độ ổn định để chuyển hóa đường thành rượu và hỗn hợp các sản phẩm phụ: nước và bã gọi là giấm chin (cơm hèm)

4. Distillation and purification

Using numerous distillation towers (eight to ten towers) is a unique aspect of this procedure. For all pollutants to be totally removed, this is the equivalent of filtering through eight or ten times.

Then, alcohol with a high concentration, up to 96 degrees of alcohol, is mixed with purified water to produce alcohol with a lower concentration. Finally, the wine will be matured for several months before it's brought to the market.

Industrial yeast and its purposes

1. What is industrial alcohol yeast?

Industrial wine yeast simply functions to convert sugar into alcohol, in contrast to conventional herbal yeast cakes and leaf yeast. These types of yeast are chosen in order to maximize the efficiency of alcohol production. As an illustration, the Saccharomyces yeast strain may thrive at 28 to 30 degrees Celsius with a PH concentration of 4.5 to 5.5.

2. Industrial wine yeast shape and features

Industrial alcohol yeast is divided into two forms: liquid form and powder form. Typically, pale yellow, milky white, or white.

Feature:

- Industrial flavor: Owing to the unadulterated composition of microbial wine yeast, the final wine is devoid of "Vietnamese spices" derived from other yeast and mold strains. These yeast molds are typically seen in leaf yeast cakes and traditional herbal yeast cakes.

- Clean: Yeasts and molds impart a distinct flavor to traditional yeast cakes, producing undesirable compounds such as aldehydes, esters, acids, and so on. However, because industrial alcohol yeast solely uses the Saccharomyces yeast strain, it creates no (or few) by-products, resulting in the high purity of industrial alcohol. men rượu công nghiệp chỉ sử dụng dòng nấm men Saccharomyces nên không (ít) sinh ra các sản phẩm phụ, đây là nguyên nhân dẫn tới độ tinh khiết cao của rượu công nghiệp.

- Rapid alcohol production: High-performance yeast strains with short alcohol production times are used by industrial wine makers, who also place great emphasis on alcohol production efficiency.

Conclusion

The ultimate criterion for every wine maker is alcohol yeast. The manufacturer selects the right yeast strain based on the cultural traits of each area. Due to the influence of foreign cultures, vodka held a significant market share in Vietnam before to 2018 (dominant with traditional alcohol). However, that tendency has faded and traditional alcohol in bottles is gradually taking control. That demonstrates how traditional alcohol items always have a special place in the hearts of Vietnamese people.